Recordall® Turbo 2000 Meter RTS-T-6 9-10 DESCRIPTION Badger Meter offers the 6' Turbo Series meter in Cast Bronze and a Low Lead Alloy. The Cast Bronze (Trade Designation: Turbo Series B81-NS) and the Low Lead Alloy (Trade Designation: Turbo Series LL-NS) versions comply with ANSI/NSF Standard 61, Annex G and carry the NSF-61 Mark on the product. This is the user manual for the High Resolution (HR) LCD encoders. Any changes made by the user not approved by Badger Meter can void the user’s authority to operate the equipment. Industry standard ASCII encoded output.HR-E LCD encoders are designed for use with all current Badger Meter Recordall® Disc, Turbo Series, Compound. To replace an existing meter, continue with Step 6. To install a new meter, skip to Step 8. Loosen meter couplings or flange bolts and remove the meter and the old gaskets in the coupling nuts. IMPORTANT Badger Meter recommends that you replace the entire connection set at the time of meter replacement or if conditions require.

MAINTENANCE

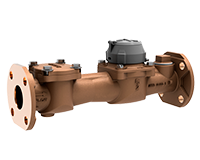

- Meter Installation: The meter is designed for installations where flow is in one direction only. Companion flanges for installation of meters on various pipe types and sizes are available in cast iron or NL bronze as an option. See the Recordall Turbo Series Meters User Manual for specific instructions.

- Badger meter Recordall Turbo Series Pdf User Manuals. View online or download Badger meter Recordall Turbo Series User Manual.

This section is limited to information pertaining to the general maintenance of Badger

Meter Recordall Compound Series

meters An exploded view of the meter, along with part numbers and descriptions, are provided in the Recordall Compound

Series Meters Parts List

Accuracy Testing

The Compound Series meter can be tested for accuracy with a test meter or a test tank of known volume A test plug is

provided on the meter The low flow register is for recording the amount of water passing through the disc, or low flow side

of the meter The high flow register is for recording the amount of water passing through the turbo, or high flow side of

the meter

When testing at flow rates below the meter’s cross-over point, only the low flow test hand will move Record the initial reading

(low flow odometer and low flow test circle) To determine the amount of water that has passed through the meter during

test, take the new reading from the low flow test circle If more than one revolution of the test circle, take a new reading from

both the low flow odometer and the low flow test circle The difference between the initial and final reading is then compared

to that recorded by the test meter or test tank

When testing flow rates at or above the meter’s crossover point, the high flow and low flow register test hands will move

This is because both sides of the meter, disc and turbo, operate simultaneously at these flow rates The disc side of the meter

operates at all flow rates to keep the chamber free of debris that might enter the meter Record the initial readings (high flow

odometer and high flow test circle, low flow odometer and low flow test circle) If less than one revolution of the high flow

test circle, record both the new high flow and low flow test circle readings The amount of flow recorded by the high flow and

low flow test circles during test must be added together to determine the total flow through the meter Compare this to that

recorded by the test meter or test tank

If more than one revolution of the high flow test circle occurs, take new readings from the low flow odometer, high flow and

low flow test circles and add all complete high flow test circle revolutions to this Once again, the amount of flow recorded by

the high flow and low flow test circles must be added together and combined to determine the total flow through the meter This

is then compared to that recorded by the test meter or test tank

A simplified alternative to recording the initial and final odometer readings on the high flow and low flow odometers, is to

record the number of complete revolutions of the test hand on the high flow and/or low flow test circles during test This is

then added to the difference between the initial and final position of the test hands on the test circles to determine the total flow

through the meter

For correct testing procedures, and test volumes based upon meter flow rates, please refer to AWWA M-6 Manual Starting the

test when the register test circle hands are on zero and operating the meters through complete revolution of the test circles

are desirable operating procedures to follow

THE TEST HANDS OPERATE INDEPENDENTLY OF ONE ANOTHER. FOR EXAMPLE, DURING METER OPERATION AT FLOWS

BELOW CROSSOVER, THE LOW FLOW TEST HAND WILL REVOLVE WHILE THE HIGH FLOW TEST HAND IS STATIONARY,

Badger Recordall Compound Meter

ALLOWING HIGHER READINGS ON THE LOW FLOW ODOMETER ONLY.

Maintenance Equipment

The tools and equipment recommended for use in servicing and maintaining of Recordall Compound Series meters consist of

the usual complement of hand tools used by plumbers and mechanics

Preventive Maintenance

The purpose of preventive maintenance is to ensure efficient operation and long life of the meter by detecting and correcting

any defect that might damage the meter or cause it to fail Preventive maintenance consists of periodic inspection, accuracy

testing, and cleaning procedures

Recordall® Compound Series Meter, Sizes 2', 3', 4' and 6'

Page 10

September 2013

Installation manual, Recordall® disc series meters, Safety information

Recordall® Disc Series Meters

Cold Water Disc Meters, 5/8' to 2'

Installation Manual

RDM-UM-00059-EN-03 (May 2013)

SAFETY INFORMATION

The installation of the Recordall® Disc Series Meters must

comply with all applicable federal, state, and local rules,

regulations, and codes.

Failure to read and follow these instructions can lead to

misapplication or misuse of the Recordall® Disc Series Meters,

resulting in personal injury and damage to equipment.

PRODUCT UNPACKING AND

INSPECTION

Upon opening the shipping container, visually inspect the

product and applicable accessories for any physical damage

such as scratches, loose or broken parts, or any other sign of

damage that may have occurred during shipment.

NOTE:

N

If damage is found, request an inspection by

the carrier’s agent within 48 hours of delivery

and file a claim with the carrier. A claim for

equipment damage in transit is the sole

responsibility of the purchaser.

METER PRE-INSTALLATION

Take into account the following considerations before you

begin an installation:

• Inspect the piping around the meter setting for suitable

conditions. The service line, valves, connections and

meter must be watertight. Repair the piping system if

pipes are corroded or damaged.

• Set the meter in a horizontal position with flow in the up

direction. Registration should be upright and protected

from damage, freezing, and tampering.

• Position the meter so it is accessible for installation,

removal and reading.

• Verify that a suitable electrical grounding wire is properly

Badger Meter Recordall 6 User Manual Download

attached to the upstream and downstream pipe

connections of the meter. The grounding wire provides

an alternative path for any electrical current that may

exist across the opening in the line.

•

Close the curb (shut-off) valve to relieve water pressure

in the line before starting the cutting operation. Provide

a high-quality upstream shut-off valve with a low

pressure drop.

•

When cutting into a new section of service pipe,

flush the pipe to clear chips, pipe dope or other

plumbing residue.

•

The installed meter must not be an obstacle or a hazard

to the customer or interfere with public safety.

•

DO NOT ATTEMPT TO USE ANY METER AS A LEVER OR

CROWBAR TO STRAIGHTEN A MISALIGNED METER

SETTING. THIS COULD DAMAGE THE METER.

•

DO NOT ATTEMPT TO SET A METER INTO AN OPENING

THAT IS TOO LONG BY FORCING THE PIPING INTO

PLACE WITH THE METER'S COUPLING NUTS. THIS WILL

CAUSE SERIOUS DAMAGE TO THE THREADED ENDS OF

THE METER AND HOUSING.

To avoid potential problems, correct any irregularities in pipe

spacing and misalignment before placing the meter into

its setting.