Ryobi BT300 User Manual. Service, How to order repair parts, For use with ryobi bt3000 table saw. Ryobi Power saws. Manuals Directory ManualsDir.com - online owner manuals library. Ryobi manuals.

Repair Parts Home Power Tool Parts Ryobi Parts Ryobi Table Saw Parts Ryobi BT3100-1 10' Table Saw Parts. Hermani, pg 29 of the user manual (look for pdf online if you don't have one) shows how to adjust the rip fence. Basically the 2 black hex screws on top of the aluminum silver fence can be loosened so that the alignment can be adjusted. TABLE SAW - MODEL NO. PARTS LIST-FIGURE 59-CONT'D. WARNING: Improper electrical repair of the table saw can result in damage to the drive system possibly causing electrical shock or electrocution. Any repairs requiring disassembly of your tool require safety testing and should only be performed by a Ryobi Authorized Service. Find the user manual you need for your tools and more at ManualsOnline. Ryobi Saw BT3000. (254 mm) TABLE SAW OPERAT0R'S MANUAL BT3000. Get Ryobi BT3000 Router And Jig Saw Mounting Kit Operator's Manual. Get all Ryobi manuals! Table of your BT3000 table saw. Ryobi jig saws plus many. Your new router and jig saw mounting kit includes two. Separate mounting plates, two guide fences with guide. Nov 24, 2019 Download 239 Ryobi Saw PDF manuals. User manuals, Ryobi Saw Operating guides and Service manuals. Page 1 OPERATOR'S MANUAL 10 in. TAbLE SAw RTS10 Your table saw has been engineered and manufactured to our high standard for dependability, ease of.

OPERAT0R'S MANUAL

10 in. (254 mm) TABLE SAW / BT3000

SPECIFICATIONS:

Blade Diameter

10 in. (254 mm)

Blade Arbor

5/8 in. (16 mm)

Cutting Depth at 0

°

3-9/16 in. (90.5 mm)

Cutting Depth at 45

°

2-1/2 in. (63.5 mm)

Rating

120 Volts, 60 Hz-AC Only

15 Amperes

Output Speed

4,800 RPM

Net Weight Without Workstand

75 Lbs. (34.1 kg.)

Net Weight With Workstand

Ryobi Bt3000 Table Saw Owners Manual

107 Lbs. (48.6 kg.)

Save This Manual For Future Reference

CONGRATULATIONS AND THANK YOU FOR BUYING THIS RYOBI 10 in. PRECISION CUTTING SYSTEM.

Your new saw has been engineered and manufactured to Ryobi's high standards for dependability, ease of operation, and

operator safety. Properly cared for, it will give you years of rugged, trouble-free performance.

CAUTION: Carefully read through this entire operator's manual before using your new saw.

Pay close attention to the Rules for Safe Operation, Warnings, and Cautions. If you use your saw properly and only for what

it is intended, you will enjoy years of safe, reliable service.

A Neutral Review on Ryobi BT3000 From A Loyal Fan

When I shopped for a table saw, I compared the Ryobi with others available at around the same price. Since I grew up using the Delta contractor saw which is also used by my best friends, I naturally was inclined by product loyalty alone to choose the Delta.

When making this comparison, as far as I could tell, the Delta hasn’t changed in basic concept, design, and function in over twenty years. In fact, it’s an American woodworking icon. Although the other brands of table saws in the same price range may offer improvements to the basic Delta design, they never-the-less follow the same basic, bare-bones, table saw concept.

Ryobi Bt3000 Table Saw Specifications

In contrast, the Ryobi’s designers appear to have broken the traditional table saw mold by re-engineering the basic table saw using the latest materials and manufacturing techniques. In the process, Ryobi has produced a comparatively more modern and versatile wood cutting platform than the bare-bones table saws offered by its competitors for the same money. This is readily apparent in the extensive use of cast and extruded aluminum construction, the detachable/moveable tables and rip fence guide bars and the sliding miter table.

Naturally, I suspected that all of these lightweight “improvements” and moveable parts may be prone to “play” and “slop” requiring frequent re-adjustment and tightening. I was concerned that, cumulatively, these lightweight improvements would render the machine comparatively “antsy” and delicate causing it to be an overall annoyance, rather than a pleasure, to use.

Below is my appraisal of the basic saw’s performance. Attachments such as an outfeed table, fence guide and side table extensions, and sliding miter table workpiece clamp are also available.

Cutting and Ability to Hold Settings

For over 2.5 years I’ve been using the Ryobi BT3000 while working from mostly large pieces of rough sawn 5/4 and 2″ oak. I couldn’t be more pleased with it’s consistent “dead-on” accuracy and cutting performance. In fact, I routinely expect to get consistently jointer clean, no-burn, cuts from my machine. By virtue of these consistently mirror clean cuts, I can only conclude that the Ryobi has zero, or, very little arbor run out. My friends who have the Delta’s are impressed.

Since I’m still in the process of setting up my shop, I need to move may saw around my garage to get it into position most times when I use it. Its lightweight makes this transport easy. This frequent movement including inevitable smacks into other equipment, etc., has not ever adversely affected its settings.

Periodically when my cuts begin to degrade, I check alignments only to find that my blade needs re-sharpening. I use the standard Ryobi blade (Made by Freud) and a Freud back-up. Since I am already getting perfectly clean cuts I wonder if the Forrest blades recommended in rec.ww could improve performance by either cutting faster, or, by lasting longer between re-sharpenings.

Just for good measure, on a few occasions usually before commencing new projects, I’ll go over the whole saw “tweaking” and spot lubing my equipment – just like I would with any piece of power equipment. More often than not, any required “tweaking” is only to improve upon the last settings that I had previously dialed in. And like most table saws, once you get the hang of its adjustments, it’s easy.

With the Delta contractor saw, and particularly with the standard Delta contractor saw fence, this tweaking is the almost necessary ritual for just about every cut. By virtue of the fact that the standard Ryobi extruded aluminum rip fence works as a “T” clamp, that locks down both front and back, it stays dead-on parallel with the blade. In use, the fence glides lightly on the extruded aluminum guides which is a plus when sneaking up on scribe marks for final fine line cuts.

It kills me to hear people favorably comparing other table saw in this price range to the Ryobi while in the same breath stating that the standard fences are trash and recommending aftermarket fences for an additional $200.00 to $300.00.

Unlike the stock rip fences of these other table saw’s of the same price range, the Ryobi’s stock rip fence works very well. Furthermore, since it locks down rock solid, it can also be used as an accurate and solid base for other sliding jigs. I understand Ryobi is also coming out with a micro adjuster for their rip fence.

Compared to the standard miter gauges on the other table saw’s of this price range – even when modified/faced with wood extenders to better support the workpiece – the sliding miter table is, hands-down, a much more effective means to achieve accurate crosscuts and miter cuts of stock up to 16″ wide.

By eliminating much of the friction/drag of both the miter gauge and workpiece on the table, the sliding table smoothly glides the workpiece into and through the blade in a much more controlled motion throughout the cut. It is a real pleasure to use; particularly in fine line work.

Despite its many detachable parts and my use of it cutting heavy, rough sawn oak material, plus, my frequent transport/movement of the entire saw, the Ryobi BT3000 holds it’s settings very well. Overall, the saw can be tuned to very exacting, “bang-on” tolerances and it maintains these settings/”bang-on” tolerances very well.

In sum, through heavy use, the saw has unequivocably eliminated my original concerns of its delicacy and inability to hold it’s settings. Furthermore, it’s consistently clean cuts and the silky smooth movement of the fence and sliding miter give it a nice feel that supports its “precision cutting system” label.

Safety

In my view, besides the blade guards, the most important safety item on a table saw is a well-placed easily operated on/off switch. The Ryobi has the largest, and easiest to use the switch that I have ever seen on any table saw, bar none at any price range. When the sh*t literally starts hitting the fan I don’t want to be dodging flying debris while groping around under the table trying to stop the saw.

The wide flat surface area of the Ryobi’s “off” switch makes it easy to reach under the table and slap off fast – NOW – w/o taking one’s attention from any potentially dangerous” developments” on the table surface.

Dust Collection

The Ryobi’s blade is fully enclosed under the table in a cowling which feeds into a cast-aluminum dust chute which, in turn, fits standard Shop Vac hoses. In addition, the Ryobi provides a switched 110V receptacle that is activated when switching-on the saw so that the shop vac turns on automatically with the saw. With Ryobi’s close clearance throat insert and with a shop vac attached, sawdust is virtually eliminated. The other table saw’s of comparable cost have nothing for dust collection.

Recently after my friend cut up a couple of sheets of particle board on his Delta contractor table saw, he called asking me to inquire of rec.ww if anyone had Delta contractor table saw dust collection plans. I understand the Delta can be rigged for dust collection. that with an enclosed bottom cabinet and foam inserts around the other Delta table saw cabinet openings. The Ryobi comes with built-in dust collection ability lacking only a simple shop vac.

Versatility

With it’s detachable/moveable tables and fence guides, the Ryobi can be configured to cut with equal versatility and cut capacity on either side of the blade. One of the detachable tables includes an aperture for mounting a router eliminating the need for a separate router table. If bought the separately similar table saw router extension tables for the Delta cost about $140.00.

Furthermore, by unplugging the table saw from the switchable receptacle and then plugging in the router, the easily accessible and safe table saw on/off switch, mentioned above, can be used to activate and turn off the router.

And as mentioned the Ryobi is much more transportable/movable than its competitors.

Unfavorable Reports

Since the Ryobi BT3000 has not been online for many years, the proof of its fundamental reliability is still in the pudding. However, I have heard one ex-user report multiple belt failures.

Lack of a miter gauge slot is the most frequent criticism reported. However, I understand that Ryobi is coming out with a detachable table which has parallel miter slots.

I just made a combination jig for; tenoning and box joint cuts, plus, panel edge cutting/slotting and/or panel edge beveling/panel raising. This jig rides on a sleeve which envelopes and slides on/over the rip fence. Since the Delta’s stock fence has adjusting screws protruding along the top edge preventing anything from sliding on top, this jig could not be used with the Delta.

Alternatively, if you decide to buy the Ryobi, you may want to get the miter slotted table in order to use the Delta tenoning jig ($90.00 +) and/or the Woodcraft box joint jig ($95.00+).

Others have reported problems with the need for frequent readjustment of the Ryobi’s settings. However, my own and others’ experiences reported here seem to flatly refute these reports. It should be noted that the Ryobi is a fundamentally different table saw then what many are used to handling and setting-up; particularly with the inclusion of the sliding miter table which requires additional settings that most former table saw users would not be familiar with making.

For example, the Ryobi has a basic set-up sequence which, if done out-of-sequence, will result in the whole sliding table and miter gauge works being out of whack. The sliding table must first be set to slide precisely in parallel with the blade, then the miter gauge can subsequently be set 90 degrees to the blade.

If the sliding table’s “parallelism” is not set first, then although the miter gauge may align at 90 degrees at one point of the slide, it will be off-kilter at all other points along the slide.

Since the manual is so well illustrated and easy to follow, and the actual adjustment process is really very simple (if the manual is followed), it is difficult to understand how the basic set-up could be fouled up – unless there was a lack of understanding of the necessity to proceed in proper sequence as explained above. I suspect this may be the case with those having trouble keeping the Ryobi set properly.

Alternatively, if the Ryobi’s set/adjustment screws were prone to self-loosening under operation, then I could understand the need to constantly re-adjust the saw. But I have never heard of this problem of the Ryobi’s adjustment screws coming loose.

To the contrary, in my experience, the saws’ adjusting screws and hex nuts have always remained tight with the settings that I had originally dialed in. With the Ryobi, I had no one to blame for its settings and/or inaccurate cuts but myself.

I’ve read that some unfavorably evaluated the Ryobi’s universal motor and prefer continuous use motors instead. I don’t know the difference and would appreciate any FAQ source or material on this subject.

For all, I know this could be a liability in the long run. But I also read that the Delta comes with a universal motor as well.

My own pet peeve with the Ryobi is that the throat plate sits about 1/64th below the table surface. When making thin rips on workpieces narrower than the throat plate, the piece lurches into this slight, 1/64″ recess if you don’t keep extra pressure on the piece against the fence. It’s not a problem that I encounter very often but it’s an annoyance nonetheless. I guess I could glue shims to the reverse of the throat piece to bring it up flush.

Lastly, I’ve read one rec.ww member write that he had compared the Ryobi with the others of the same price and decided against the Ryobi based on a report that the noise output of the Ryobi motor was higher than the others.

No doubt, when you wind up the Ryobi you definitely are made aware by its serious aircraft-like whine that, despite its smooth appearance, this machine is as potentially dangerous and nasty as any of its competitors. I personally like this high-tech, high pitch nasty whine and only wish my monster Shop Vac didn’t drown it out.

Be forewarned that the Ryobi BT3000 is subject to considerable criticism in this newsgroup; Most of which criticism is flatly refuted by my own and others’ favorable experience with the Ryobi BT3000.

If properly set-up and handled, it is a fine wood cutting machine for the money. Don’t let its smooth looks deceive you. It’s a hard-working machine that has easily handled everything that I’ve ever thrown at it.

I suspect that the Ryobi BT3000’s fresh concept has drawn a certain degree of the defensive type of criticism by merely challenging the accepted American table saw icons which, after all, are fine basic saws that have rightfully earned the loyalty of many people who grew up using them and who are still using to this day.

Conclusion

I believe that due it’s lightweight and transportability, its ability to hold it’s settings so well under heavy use, combined with the standard features included in the basic package not available with other comparably priced contractor table saw’s – the Ryobi will eventually become the contractors’ choice for an on-site table saw.

Therefore, I would be surprised if the Ryobi has not challenged Delta and Jet to similarly take a fresh look at their contractor table saws with a view towards engineering into their basic saws the consistent cutting accuracy, superior safety, plus, wider cutting platform versatility available for the same price on the Ryobi BT3000.

Finally, I believe that by re-defining the basic contractor table saw to a certain degree, the Ryobi BT3000 will spark the other manufacturers to launch a whole new generation of contractor table saws.

For the record, I am not a Ryobi spokesperson. Just a loyal fan of my hardworking and reliable Ryobi BT3000.

Update The Ryobi BT3000 Accessories Diagram

I just find the Ryobi BT3000 Accessories Diagram and wish to share it with you all.

4080300: Accessory Table

It provides additional tabletop support for the BT3000SX and allows permanently mounted routers and jigsaws to be exchanged quickly and easily.

4950300: Router/Jig Saw Mounting Kit

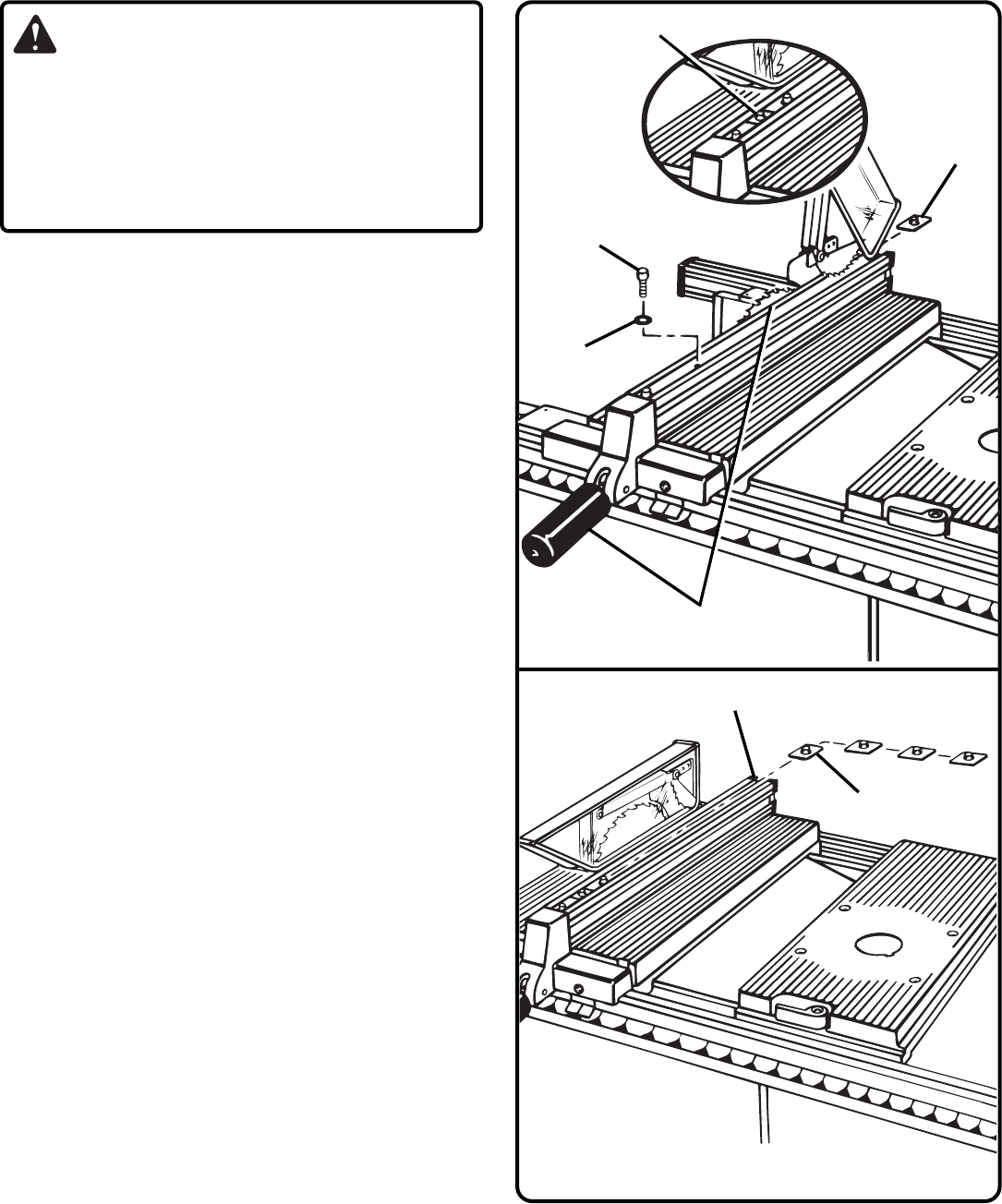

Converts the BT3000SX into an effective router table. The kit allows for the inverted mounting of various routers and jigsaws, as well as allows the rip fence to convert into a shaper fence with various adjustments.

4060300: Long Miter/Rip Fence for

Gives additional support to cut large stock accurately and conveniently. It also includes a positive stop plate for making precise repetitive cuts.

4010330: Caster Set

The set of two 4-inch casters attaches to the metal BT3000SX work stand to allow it to easily be transported around the workshop or job site.

4070330: Dado Throat Plate

Accommodates a stack of 6-1/2 inch dado blades and enhances the BT3000SX’s capacity to produce decorative cuts and precision dado joints.

4070300: Dust bag

Collects sawdust through the built-in exhaust port system, making clean-up easier than ever.

4060330: Stop Block Kit

Allows customization of the miter fence to meet specific needs.

4710300: Miter Clamping Kit

Secures stock to the miter fence by applying both down and inward pressure, which improves the accuracy of precise cuts.

4060310: Miter Slot Table

This dual-slot table has standard 3/4-inch grooves and securely mounts to the left side of the main saw table allowing for traditional methods of miter cutting and accessory applications. It also provides additional tabletop support.

4730310: Quick Fold Table

It provides additional outfeed work support when needed, and it quickly folds down and out of the way when not in use.

4080330: Table Clamp Kit

Secures the BT3000SX accessory table to provide additional strength and stability.

4730305: Wide Table Leg Set

It can be used with a wide table kit or air floatation system. The use of two sets allows the floatation table or any tabletop to be used independently from the wide table kit, as a freestanding table/work support, or clamping surface.

4730300: Wide Table Kit

Offers additional support for larger workpieces expanding the rip capacity to 72-inches. The kit includes the extension rails (up to 41-inches long) and includes brackets to mount surface table, hardware and instructions to build a leg set sup

4650324: Carbide-Tipped 10-Inch General Purpose 24T Rip Blade

For use on all 10-inch table saws.

4650340: Carbide-Tipped, Laser-Cut 10-Inch 40T Crosscut Blade

For use on all 10-inch table saws.

4650360: Carbide-Tipped 10-Inch 60T Smooth Crosscut/Fine Finish Blade

For use on all 10-inch table saws.